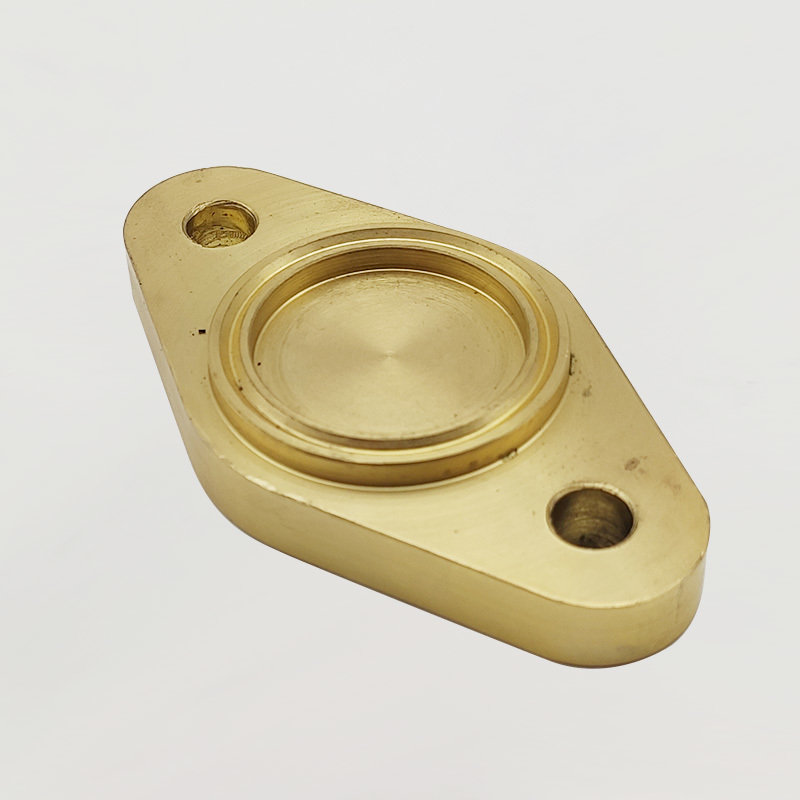

Flange Cover

Flange cover, also known as blind flange or blind flange, is a metal component used to close pipe ports in piping systems. Its main function is to close the pipeline and ensure the normal operation and safe use of the pipeline system. Its structure and shape are similar to the general flange, but one end is closed and there is no connection pipe.

The features of the flange cover are as follows:

1. Material: It is usually made of cast steel, stainless steel, alloy steel and other materials, with good strength and corrosion resistance.

2. Standards: According to different pipeline systems, the standards of flange covers are also different, such as national standards, Japanese standards, American standards, etc.

3. Pressure rating: According to the pressure requirements of the pipeline system, the flange cover has different pressure ratings, such as PN10, PN16, etc.

4. Sealing performance: The flange cover has good sealing performance and can effectively prevent medium leakage.

Application Scenarios:

Flange covers are widely used in pipeline systems in petroleum, chemical, electric power, metallurgy and other industries, mainly for pipeline closure, isolation and maintenance. In the pipeline installation, maintenance or maintenance, you can use the flange cover to close the pipeline port, to prevent the media leakage or pollution.

Flange Seat

The flange seat is a connection device used to connect pipes and other equipment, such as valves, pumps, etc. It is a metal part that connects two or more pipe ports by bolts to realize the connection of the pipe and the connection of the equipment.

The characteristics of the flange seat are as follows:

1. Structure: It is usually composed of two symmetrical flanges and connecting bolts, and the two flanges are tightly connected together by bolts.

2. Material: Similar to the flange cover, the flange seat is also made of cast steel, stainless steel, alloy steel and other materials.

3. Type: According to different connection methods and usage scenarios, there are many types of flange seats, such as plate flat welding flange seats, flat welding flange seats with neck, etc.

4. Sealing performance: It has good sealing performance and can effectively prevent medium leakage.

Application Scenarios:

Flange seats are widely used in pipeline systems in petroleum, chemical, electric power, metallurgy and other industries. They are mainly used to connect pipes and equipment to realize the transmission and exchange of media. During pipeline installation, maintenance or overhaul, equipment and pipelines can be connected or replaced through the flange seat to ensure the normal operation of the pipeline system.

In addition, the flange seat is also often used in the need for frequent disassembly and assembly of the occasion, such as the connection of the valve, the connection of the pump. Because of its simple structure, easy installation and good sealing performance, the flange seat has become an indispensable connection equipment in the pipeline system.

In general, the flange cover is mainly used for pipeline closure and maintenance, while the flange seat is mainly used for connecting pipes and equipment. Both play a very important role in the pipeline system to ensure the normal operation and safe use of the pipeline system. When selecting and using, it is necessary to determine the appropriate type and specification according to the specific scene and requirements. At the same time, it is also necessary to pay attention to its material, pressure rating, sealing performance and other parameters to ensure its performance and safety. The above is a detailed introduction to the flange cover and flange seat, and I hope it will be helpful to you.

Flange cover flange seat

Key words:

Classification:

Recommended Products

The company has always been committed to improving product quality and production equipment level, the introduction of CNC machining center, gantry machining center, general milling, drilling, grinding and other machining equipment, as well as aluminum alloy casting, infiltration production line.