Overview

In the automotive and engine industries, the intake manifold gasket is an often overlooked but crucial component. It plays a key role in the entire engine system and provides the necessary support and guarantee for the normal operation of the engine. This article will introduce in detail the functions, types, applications, and key points for purchasing and installation of the intake manifold gasket.

Function

The intake manifold gasket is an important link between the engine intake manifold and the vehicle body. Its main functions include:

1. Support function: The intake manifold gasket provides a stable support for the intake manifold to ensure that it will not loosen or shift due to vibration during vehicle driving.

2. Heat insulation function: The gasket can effectively isolate the heat conduction between the intake manifold and the vehicle body, and protect the normal operating temperature of the engine system.

3. Noise control: The intake manifold gasket also has the function of sound absorption and noise reduction, reducing the interference of engine noise on the cab.

Classification

Types of intake manifold gaskets According to different materials and uses, intake manifold gaskets can be divided into the following categories:

1. Rubber gaskets: suitable for most models, with good elasticity and wear resistance, and moderate price.

2. Aluminum alloy gaskets: suitable for high-performance models, light weight, good thermal conductivity, and corrosion resistance.

3. Composite material gaskets: Combining the advantages of multiple materials, suitable for special environments and high-demand application scenarios.

Application

Intake manifold gaskets are widely used in various power systems such as automobiles and motorcycles. With the continuous development of the automotive industry, intake manifold gaskets are increasingly used in the fields of high-performance racing cars and modified cars. In addition, it is also widely used in power equipment such as engineering machinery and generator sets.

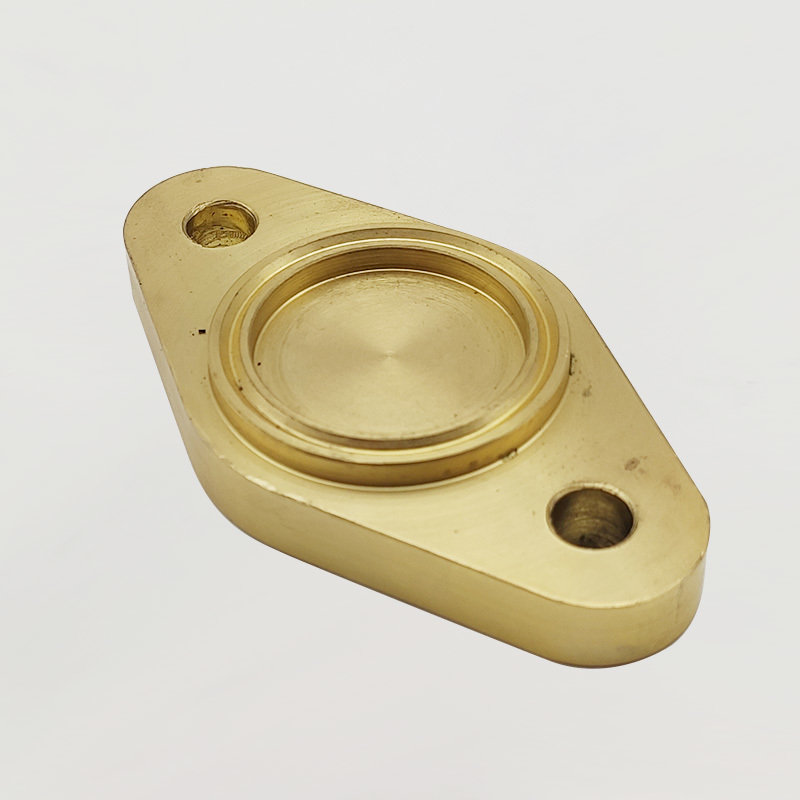

Intake pipe cushion block

Classification:

Recommended Products

The company has always been committed to improving product quality and production equipment level, the introduction of CNC machining center, gantry machining center, general milling, drilling, grinding and other machining equipment, as well as aluminum alloy casting, infiltration production line.