Overview

In the modern industrial field, as an important fluid control component, the reversing valve is widely used in hydraulic and pneumatic systems. The reversing valve housing is a key component of the reversing valve, and its performance and quality directly affect the efficiency and life of the entire reversing valve. This article will introduce the relevant knowledge of the valve housing in detail, including its function, structure, materials, manufacturing process and application fields.

Function

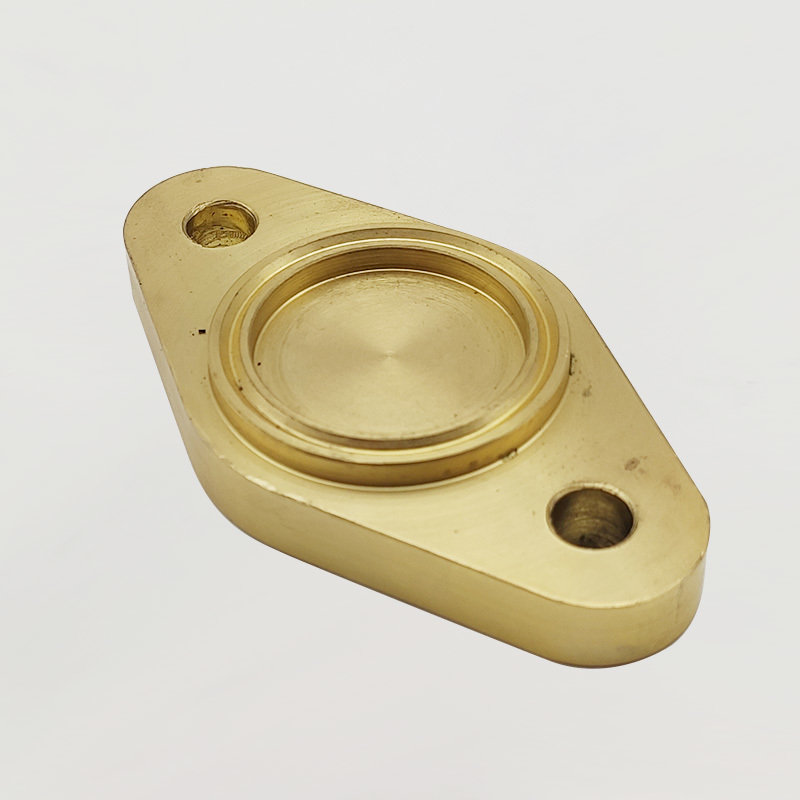

The reversing valve housing mainly plays a supporting, fixing and protecting role. In the hydraulic system, the reversing valve realizes the control of various actions by changing the fluid flow direction. The reversing valve housing ensures the smooth flow of the valve body, so that the fluid can smoothly enter and exit the valve body, so as to achieve the desired action. In addition, the housing can effectively protect the parts in the valve body from the external environment and improve the service life of the reversing valve.

Structure

The structure of the reversing valve housing is various, such as casting housing, welding housing and die-casting housing. The casting shell has high strength and rigidity, and is suitable for high pressure and large flow hydraulic systems. The welded shell has high sealing performance and is suitable for occasions with high requirements. Die-cast housing has the advantages of small size and light weight, and is widely used in pneumatic systems.

Materials

Commonly used materials include cast iron, steel, aluminum alloys, etc. The cast iron shell has good wear resistance and corrosion resistance, and is suitable for harsh working environments. The steel shell has high strength and rigidity and is suitable for high-pressure systems. The aluminum alloy shell has the advantages of light weight and good thermal conductivity, and is widely used in occasions where weight is required.

Reversing valve housing

Key words:

Classification:

Recommended Products

The company has always been committed to improving product quality and production equipment level, the introduction of CNC machining center, gantry machining center, general milling, drilling, grinding and other machining equipment, as well as aluminum alloy casting, infiltration production line.