Overview

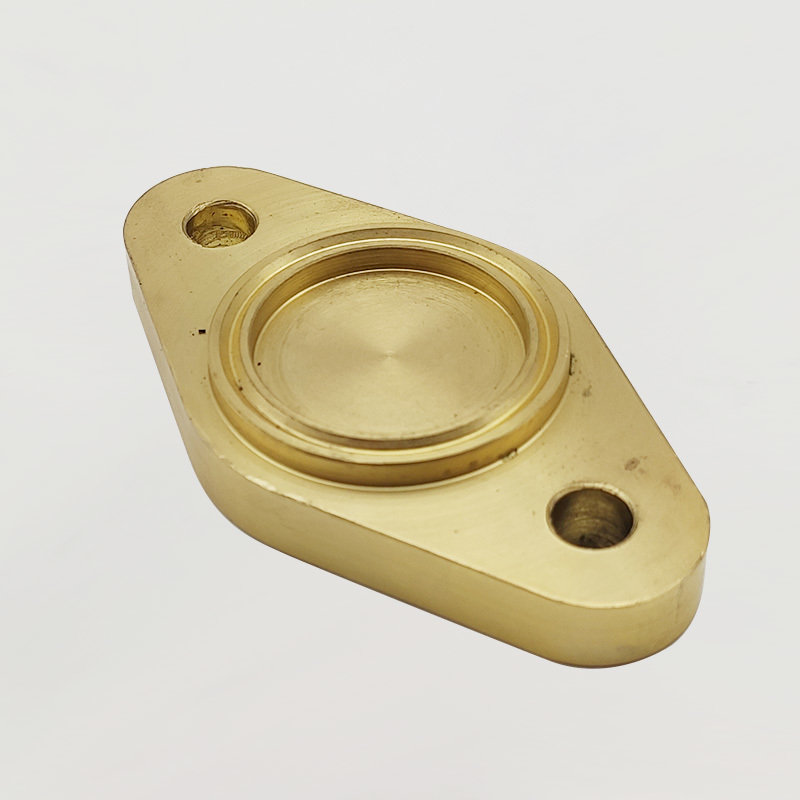

The rotary motor housing is an important part in the mechanical field, its main function is to support and accommodate the moving parts inside the motor to ensure the normal operation of the equipment.

Materials

In order to ensure the strength, wear resistance and corrosion resistance of the rotary motor shell, the commonly used materials are mainly cast iron, cast steel and aluminum alloy. Cast iron has good wear resistance and casting performance, and is suitable for motor housings of large equipment; cast steel has high strength and wear resistance, and is suitable for occasions that bear large loads; aluminum alloy has low density and light weight The characteristics are suitable for occasions with higher requirements on weight.

Manufacturing Process

The manufacturing process of the rotary motor shell mainly includes casting, machining and heat treatment. Casting is the main process of manufacturing shell, its process includes mold making, melting, pouring and cooling steps; machining is mainly used for shell finishing, including turning, milling, drilling and other processes; heat treatment can improve the mechanical properties of materials, improve its performance, including annealing, normalizing, quenching and tempering processes.

Application

Slewing motor housing is widely used in excavators, loaders, cranes and other types of construction machinery, as well as construction machinery, agricultural machinery and other fields.

Swing motor housing

Key words:

Classification:

Recommended Products

The company has always been committed to improving product quality and production equipment level, the introduction of CNC machining center, gantry machining center, general milling, drilling, grinding and other machining equipment, as well as aluminum alloy casting, infiltration production line.