Overview

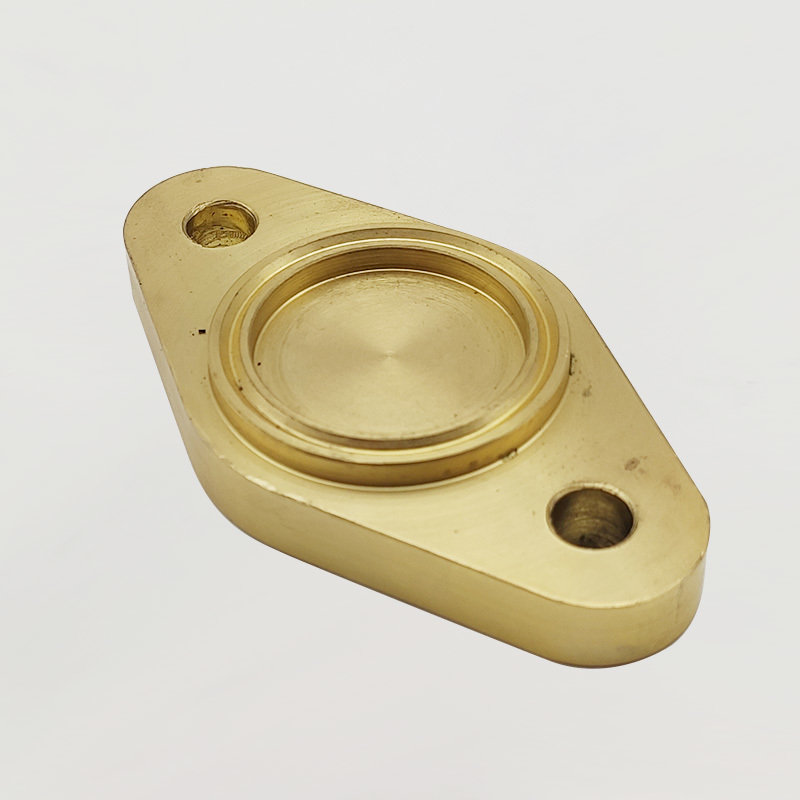

In the coal mining industry, gear box, as one of the key equipment, plays a vital role in ensuring the normal operation of coal mining and transportation. As an important part of the gearbox, the performance and quality of the gearbox cover directly affect the safety and service life of the whole equipment. Therefore, it is necessary to introduce the end cover of casting gearbox in coal mine industry in detail.

Function of Gear Box End Cover

1. Closed function: The main function of the gearbox end cover is to close the gearbox to prevent internal gears, bearings and other parts from being eroded by external impurities and dust, and to ensure the cleanliness of the gearbox.

2. Support function: The end cover supports the bearing inside the gearbox to ensure the normal operation of the bearing and reduce the wear of the gear.

3. Heat dissipation function: some end caps are designed with heat dissipation holes or heat sinks, which helps to dissipate heat inside the gear box and maintain the normal operating temperature of the equipment.

Materials for Cast Gearbox End Cover

In the coal industry, due to the particularity of the working environment, the gearbox end cover is required to have high strength, wear resistance, corrosion resistance and impact resistance. Therefore, the commonly used casting materials mainly include high strength cast iron (such as ductile iron), cast steel and so on.

The production process of casting gear box end cover

1. Mold making: Make molds according to product drawings to ensure the accuracy and life of the molds.

2. Casting: Use appropriate casting processes, such as sand casting, precision casting, etc., to ensure the quality of the castings.

3. Cleaning: Clean up the castings to remove excess sprue, slag shell, etc.

4. Heat treatment: heat treatment as needed, such as normalizing, quenching, tempering, etc., to improve the mechanical properties of castings.

5. Processing: Machining the castings to meet the accuracy requirements of the product drawings.

6. Inspection: quality inspection of the finished product to ensure that the quality of the product meets the standard.

Features of gearbox end cover

1. High strength: high strength material casting, with high strength and impact resistance.

2. Good wear resistance: the surface of the end cover is specially treated, which has good wear resistance and can extend the service life of the equipment.

3. Corrosion resistance: It can adapt to the special environment of coal mining industry and has good corrosion resistance.

4. Good heat dissipation: some end caps are designed with heat dissipation structure, which helps to dissipate heat of the equipment.

5. High precision: the use of advanced production technology to ensure that the accuracy of the product meets the requirements.

Gearbox end cover

Key words:

Classification:

Recommended Products

The company has always been committed to improving product quality and production equipment level, the introduction of CNC machining center, gantry machining center, general milling, drilling, grinding and other machining equipment, as well as aluminum alloy casting, infiltration production line.