Overview

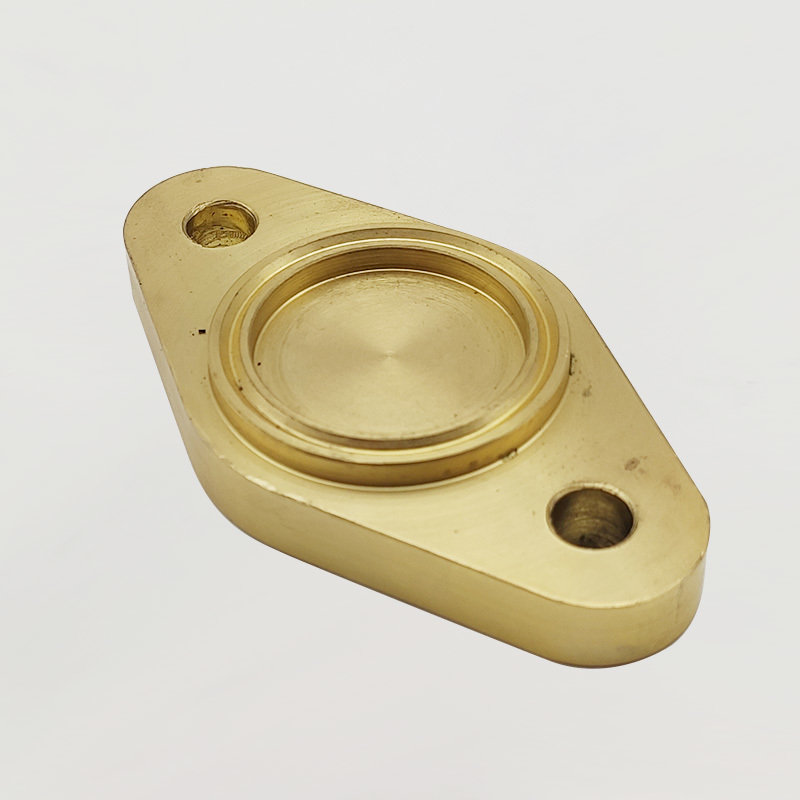

In the coal industry, in order to ensure the normal operation of the equipment and efficient work, the application of various mechanical equipment is indispensable. Among them, the gearbox is an important power transmission component, and its performance is very important to the whole system. As one of the key components of the gearbox, the valve body plays an important role in regulating fluid and controlling pressure. Casting gearbox body is an important basic component in coal mine machinery, and its quality is directly related to the safety and efficiency of the whole equipment.

The role of gearbox valve body

1. Adjusting fluid: The valve body realizes the control of fluid by opening, closing or adjusting the fluid channel to ensure the lubrication and cooling of the gearbox.

2. Control pressure: The valve body can adjust the pressure inside the gearbox to ensure the normal operation of the system and prevent equipment failure caused by too high or too low pressure.

3. Optimized performance: By accurately controlling fluid and pressure, the valve body can optimize the performance of the gearbox and improve the operating efficiency and life of the equipment.

Features

Strong wear resistance: There are a lot of dust and particles in the coal mine environment, and the valve body needs to have high wear resistance to ensure long-term stable operation.

2. Corrosion resistance: The acid-base substances and other corrosive media in the coal mine environment put forward higher requirements for the material of the valve body.

3. High strength: The valve body needs to withstand high pressure and load, so it must have sufficient strength.

4. Good sealing: The sealing performance of the valve body is directly related to the efficiency of the gearbox, so it requires good sealing.

Material

The material of the cast gearbox body is usually high-strength, wear-resistant, corrosion-resistant cast steel or cast iron. In special circumstances, stainless steel or other special materials may also be used. The choice of materials should be determined according to the specific use environment and requirements.

Production process

1. Mold making: Make the mold of the valve body according to the design requirements to ensure the accuracy and life of the mold.

2. Casting: Use appropriate casting process, such as sand casting or precision casting, to make valve body blank.

3. Heat treatment: heat treatment of the valve body, such as quenching, tempering, etc., to improve its strength and wear resistance.

4. Processing: the valve body for turning, milling, grinding and other mechanical processing, to meet the design requirements.

5. Inspection: Strictly inspect the finished valve body to ensure its performance and quality.

Gearbox valve body

Key words:

Classification:

Recommended Products

The company has always been committed to improving product quality and production equipment level, the introduction of CNC machining center, gantry machining center, general milling, drilling, grinding and other machining equipment, as well as aluminum alloy casting, infiltration production line.