Overview

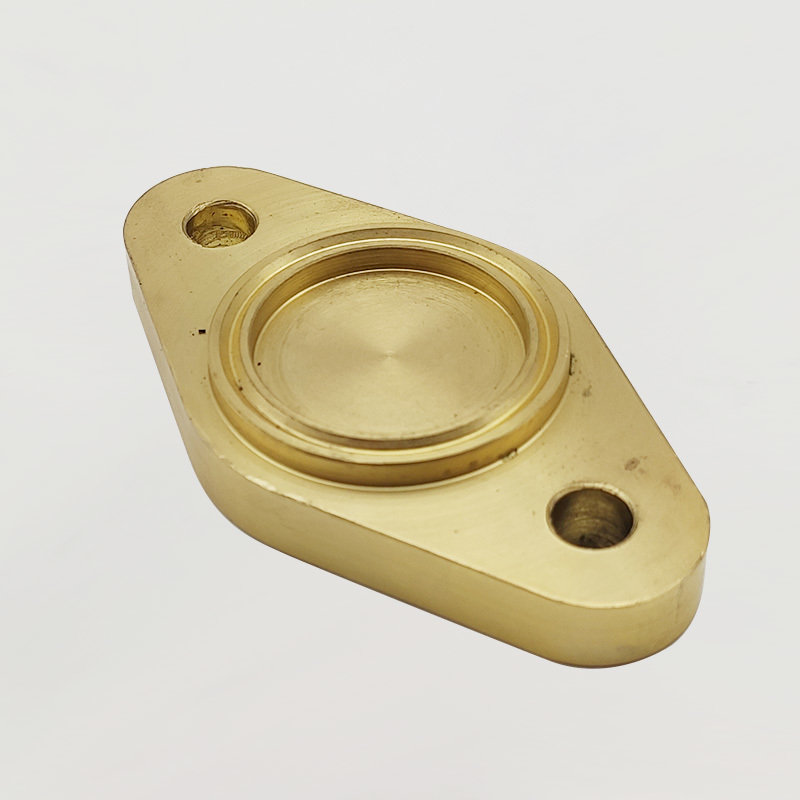

In the coal industry, the valve cover is an important part of the fluid control equipment, widely used in all kinds of valves, pumps and other equipment sealing system. The main function of the valve cover is to seal the inlet and outlet of the valve or pump body to prevent medium leakage and ensure the normal operation of the equipment. Casting valve cover is one of the most common types of valve cover in the coal mining industry, which has the characteristics of strong structure and good sealing performance.

Importance

In the process of coal mine production, the normal operation of fluid control equipment is of great significance to ensure production safety and improve production efficiency. As a key component of fluid control equipment, the performance of the valve cover directly affects the operation of the entire equipment. The material, manufacturing process and subsequent heat treatment of the cast valve cover will affect the sealing performance, strength and durability of the valve cover. Therefore, the quality of the casting valve cover is essential to ensure the smooth progress of coal mine production.

Features

1. Material: usually high-strength cast iron, cast steel and other materials, with good wear resistance, corrosion resistance.

2. Structure: The size of the valve cover is compact, with high strength and rigidity, and can withstand greater pressure.

3. Manufacturing process: It is manufactured by casting process, through precise mold design and strict process control to ensure the dimensional accuracy and surface quality of the valve cover.

4. Sealing performance: It has good sealing performance and can effectively prevent medium leakage.

5. Scope of application: suitable for all kinds of coal mine fluid control equipment, such as valves, pumps, etc.

Manufacturing Process

1. Mold design: According to the shape and size requirements of the valve cover, design a suitable mold.

2. Casting process: use appropriate casting process, such as sand casting, precision casting, etc., to manufacture valve cover blank.

3. Heat treatment: heat treatment of the cast valve cover to improve its hardness and wear resistance.

4. Machining: Machining the valve cover to ensure its dimensional accuracy and surface quality.

5. Inspection: strict inspection of the finished valve cover to ensure that its performance meets the requirements.

Bonnet

Key words:

Classification:

Recommended Products

The company has always been committed to improving product quality and production equipment level, the introduction of CNC machining center, gantry machining center, general milling, drilling, grinding and other machining equipment, as well as aluminum alloy casting, infiltration production line.